Presented here is a simple electronic circuit which can control the valve operation by sensing valid-movements with the help of a Passive Infrared (PIR) motion sensing module. In practice, automatic taps are presence sensors and not motion sensors. They employ “Active Infrared” technology which senses “presence” and not “movement” of objects. However, here an unorthodox “Passive Infrared” technology is used to realize the 6V DC powered smart faucet controller circuit.

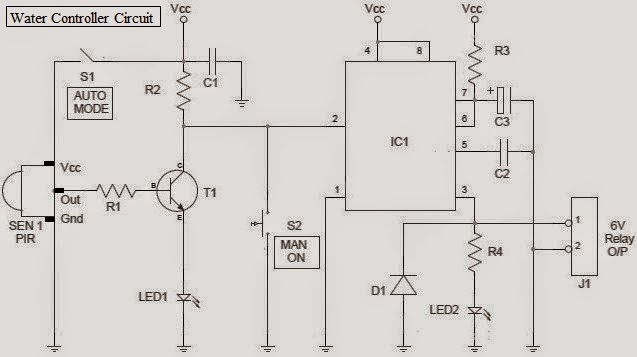

Schematic of the Water Tap/Valve Controller Circuit

Smart Valve Controller is a combination of four key components

- motion sensor with control electronics

- solenoid valve

- power source

- and the faucet

As stated, at the heart of the circuit is a Passive Infrared (PIR) module. PIR sensor is a pyroelectric device that detects motion by measuring changes in the infrared levels emitted by surrounding objects. Pyroelectric devices, such as the PIR sensor, have elements made of a crystalline material that generates an electric charge when exposed to infrared radiation. The changes in the amount of infrared striking the element change the voltages generated, which are measured by an onboard amplifier.

The device contains a special filter called a Fresnel lens, which focuses the infrared signals onto the element. The PIR Sensor requires a ‘warmup’ time in order to function properly. This is due to the settling time involved in ‘learning’ its environment. this could be anywhere from 10 to 60 seconds. During this time there should be as little motion as possible in the sensors field of view. There is a variable resistor (P1) on the PIR sensor module to control the ‘ON’ delay time for the sensor. Turning this variable resistor clockwise will give longer ‘ON’ delay time while turning anticlockwise will reduce the ‘ON’ delay time. The PIR sensor has distance range of approximately 3 to 7 meters. It is possible to adjust distance of detection with the help of the second variable resistor (P2) on the PIR sensor module.

Likewise, there is a 2-position jumper point (JP) is included in the PIR sensor module. The sensor is active HIGH (LOW in idle state) when jumper is in either position. In “retrigger” (H) position, output remains HIGH when sensor is triggered repeatedly. In “normal” (L) position, output goes HIGH then LOW when triggered. Continuous motion results in repeated HIGH/LOW pulses.

The motion sensor with control electronics circuitry is very simple and self-explanatory. Output of the PIR sensor module (SEN1) is here connected to a ‘traditional’ monostable multivibrator (MMV) wired around the ubiquitous timer chip NE555 (IC1) . Output of IC1 controls the solenoid valve through a 6V electromagnetic relay attached to J1.

Two LEDs (LED 1 & LED2) are added as system status indicators. SPDT switch S1 is the “Auto/Manual” Mode Selector. “Push – to – On” switch S2 can be used for manual operation of the faucet. Prototype tested with four 1.5V AA cells (1.5Vx4 = 6V).

Note

- Remember to set delay time & detection range of the system as low as possible by adjusting the preset pots P1 & P2 of the PIR sensor module. Removing the fresnel lens, collimation and screening by means of a piece of a suitable electrical conduit with a length of 2 to 3 cm is not a bad idea to reduce the field of view of the PIR sensor module. Place the jumper (JP) in “Normal” mode!

- Why a PIR sensor based design? PIR sensor is small, inexpensive, low power, rugged,is easy to interface with, and is easy to use. When motion is detected the PIR sensor outputs a high signal on its output pin, which can either be read by an MCU or drive a transistor to switch a higher current load.

Parts List

- SEN 1 : PIR sensor module

- T1 : BC547

- LED1 : 5mm Green

- LED2: 5mm Red

- D1 : 1N4007

- IC1 : NE555

- R1, R2: 1K

- R3 : 100K

- R4 : 470R

- C1,C2 : 100nF

- C3 : 100uF/16V

- S1 : SPST On/Off

- S2 : Push -To – On

- J1: 2-Pin male header

- Relay: 6VDC /SPST Electromagnetic Relay

Post a Comment